Our Engineering Philosophy

At Ascent Vector, engineering is our passion. We are a technology company that develops products and intellectual property based on a broad understanding of product development from concept through production. This vertically integrated knowledge helps us find innovative approaches and develop elegant solutions.

Design

Concept development and investigation is frequently the most critical phase of a project. Choices at this point often decide the result of years of work. This reality tends to push design decisions in conservative directions. At Ascent Vector, we are committed to innovation and understand that true innovation often requires substantial design risk. We manage this risk by maintaining the tools, facilities, and knowledge to quickly investigate concepts, as well as the willingness to change course when a concept does not meet our requirements.

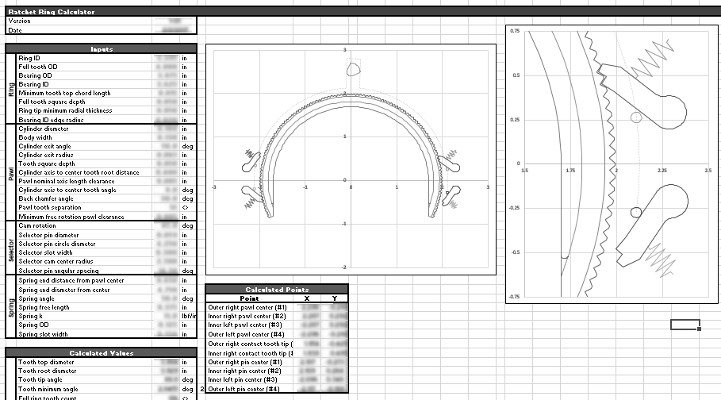

Analysis

Analysis is a critical component of managing engineering risk but is often applied in ways that leave projects vulnerable to unexpected problems. In many cases, deep analysis is performed on a small number of perceived high-risk areas while other areas are virtually ignored. At Ascent Vector we believe that analysis must start with robust system level analytical modeling. This approach provides a strong high-level understanding of a concept's risks and viability which is both relatively low cost and easier to iterate as a design changes. It also allows us to more successfully focus our in-depth analysis and make better decisions on which risks require prototyping.

Prototyping

Physical prototyping is a critical and increasingly overlooked part of the design process. Intelligent prototyping provides critical insights into the functionality of a product and insures that manufacturing and production considerations are investigated and thoroughly understood early enough in the design process that changes are possible and cost effective. At Ascent Vector we are committed to early prototyping and maintain internal prototyping facilities which allow us to fabricate prototypes ranging from single components to complete functional products in final materials and at full scale.

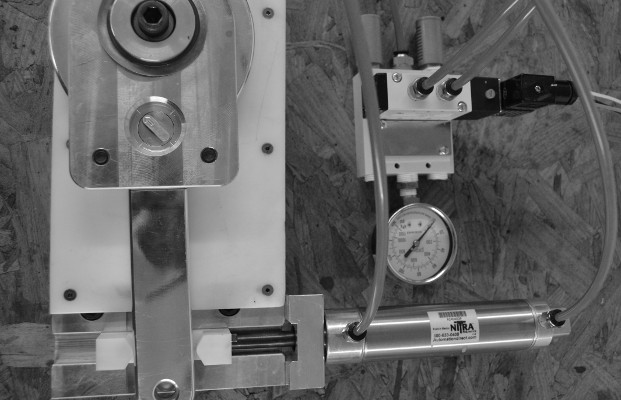

Testing

How a company tests its products demonstrates its commitment to quality. At Ascent Vector we believe in thorough testing. We strive to create realistic test conditions and then push our products to their boundaries. Our team has extensive experience designing test equipment ranging from small automated bench-top tests to multi-hundred-foot flow loops, and complex setups to test functional performance under extreme environmental conditions.

Production

Effective manufacturing is critical to delivering a viable product. Our design team’s direct involvement with physical prototyping and testing helps us optimize manufacturability early in the design cycle. Our production is significantly vertically integrated which allows us to maintain careful control over quality and maintain involvement of the same team throughout all phases of a project. When we purchase parts or components externally, we carefully select our suppliers to make sure that they will meet our quality expectations.